Starting a one-person metal mold design business, particularly in 판금 (sheet metal fabrication), can be a rewarding venture.

It combines creativity with technical skill, offering unique opportunities for entrepreneurs in the manufacturing sector.

This guide will provide you with essential information to establish and grow your business successfully.

Understanding the Market and Target Audience

Focus on continual process improvement and standardization where possible. Always reflect on how to streamline your workflow and design process.

Identifying Your NicheTips for Maintaining Quality and Efficiency in Designs:Identifying Your Niche

The metal mold design industry is diverse. Focus on a specific niche to stand out. Consider specializing in automotive parts, consumer electronics, or industrial equipment. Research market demands to find underserved areas. Analyze competitor offerings to identify gaps you can fill.

Knowing Your Clients

Understand your potential clients’ needs and preferences. Small manufacturers may need cost-effective solutions. Large corporations might prioritize precision and speed.

Hobbyists could seek customization options. Tailor your services to meet these varied requirements. Conduct surveys or interviews to gather insights directly from potential customers.

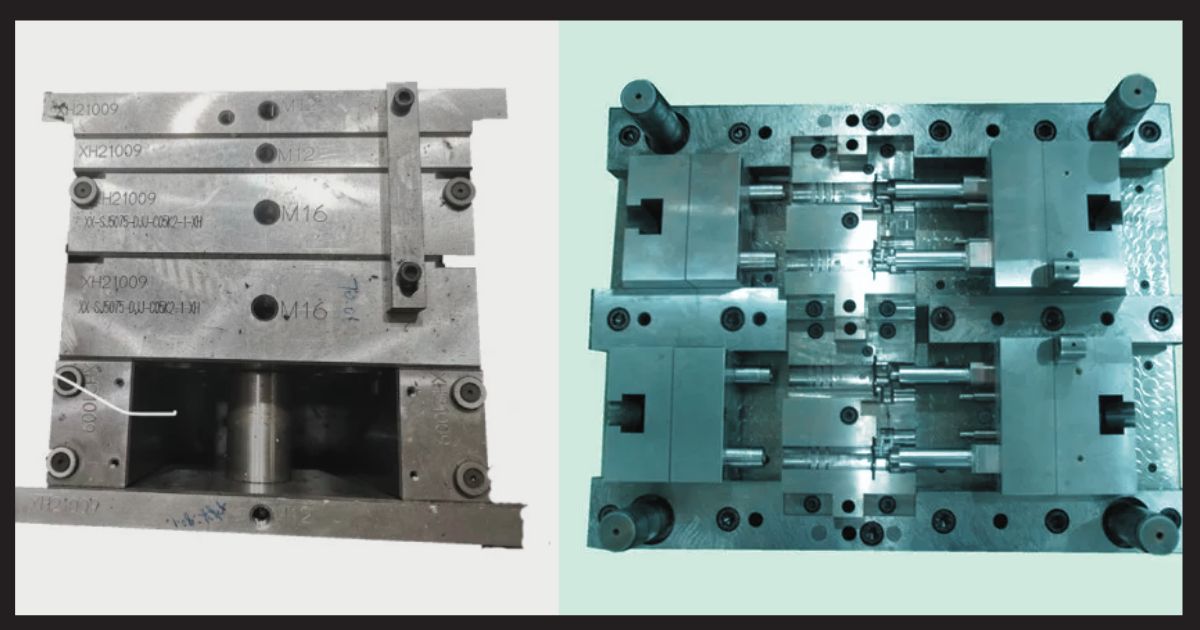

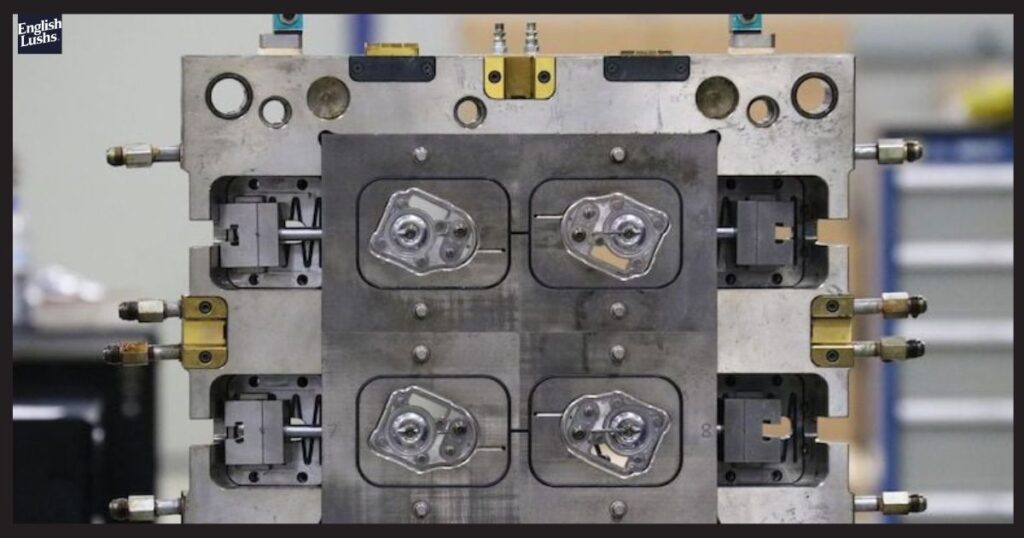

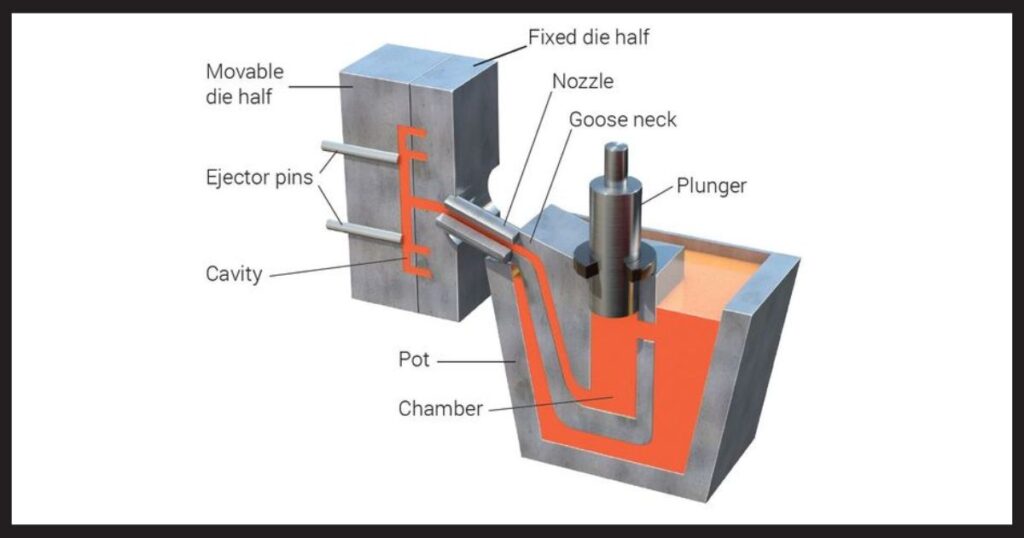

Essential Tools and Equipment for Metal Mold Design

3D CAD software is a must for digital modeling and prototyping. CNC/CAM technologies allow precision machining of molds.

CAD Software

Invest in high-quality Computer-Aided Design (CAD) software. Options like SolidWorks or Fusion 360 offer powerful features. Learn to use these tools proficiently. They enable precise 3D modeling and simulation. Stay updated with the latest software versions and features.

CNC Machinery

A Computer Numerical Control (CNC) machine is crucial. It ensures accuracy in mold production. Consider starting with a smaller, versatile model. Upgrade as your business grows. Learn to program and operate the machine effectively. Regular maintenance keeps it running smoothly.

Hand Tools and Safety Equipment

Stock up on essential hand tools. Include calipers, micrometers, and files. Don’t overlook safety gear like gloves and goggles. Proper equipment enhances precision and ensures safety. Organize tools for easy access and efficient workflow.

Setting Up a Workspace

Organize your physical work area and design space to be efficient and conducive to productivity. Maintain an ergonomic setup.

Designing an Efficient Layout

Create a workspace that maximizes productivity. Designate areas for design, fabrication, and assembly. Ensure good lighting and ventilation throughout. Consider ergonomics to prevent strain during long work hours. A well-organized space boosts efficiency and creativity.

Storage Solutions

Implement smart storage solutions for materials and tools. Use pegboards for frequently used items. Install shelving units for larger equipment and supplies. Label everything clearly for quick retrieval. Efficient storage saves time and reduces clutter.

Metal Mold Developing a Unique Style and Brand Identity

Maintain consistency in your aesthetic, messaging, materials and values to build brand recognition. Clearly define what makes your brand different from others.

Crafting Your Signature Style

Develop a distinctive design approach. Experiment with different techniques and materials. Find a balance between functionality and aesthetics. Your unique style will set you apart from competitors. Document your design process to maintain consistency.

Building a Strong Brand

Create a compelling brand story. Highlight your expertise and passion. Design a memorable logo and consistent visual identity. Use these across all marketing materials and platforms. A strong brand builds trust and attracts loyal clients.

Marketing and Networking Strategies

Attend local industry events and trade shows to promote your services and capabilities to new potential clients.Develop relationships and connections within your industry or field.

Digital Marketing Techniques

Build a professional website showcasing your portfolio. Utilize search engine optimization (SEO) for visibility. Engage in social media marketing on platforms like Instagram. Share behind-the-scenes content and finished projects regularly. Consider starting a blog to share industry insights.

Networking in the Industry

Attend trade shows and industry events regularly. Join professional associations related to metal fabrication. Participate in online forums and discussion groups. Build relationships with suppliers and fellow designers. Networking can lead to collaborations and referrals.

About Competition and Managing Business Rivalry

Manage competition professionally by focusing internally on your own strengths and vision rather than externally comparing yourselves. Develop your own strategies without regard to rivals.

Analyzing Competitors

Study your competitors’ strengths and weaknesses. Identify areas where you can offer superior services. Stay informed about their pricing and turnaround times. Use this information to refine your own offerings. Remember, healthy competition drives innovation.

Differentiating Your Services

Focus on what makes your business unique. It could be faster delivery times or specialized designs. Offer exceptional customer service to stand out. Consider providing additional services like design consultation. Continuously improve your skills to stay ahead.

Tips for Maintaining Quality and Efficiency in Designs

Implementing Quality Control Measures

Develop a systematic approach to quality assurance. Check designs at multiple stages of production. Use digital simulations to test mold performance. Implement a feedback loop for continuous improvement. High-quality output builds a strong reputation.

Streamlining the Design Process

Create templates for common design elements. Develop a library of standard parts. Use parametric modeling for quick customization. Automate repetitive tasks where possible. Efficient processes save time and reduce errors.

Collaborating with Clients for Custom Projects

Custom metal mold projects now involve real-time client collaboration through virtual design platforms. Designers are utilizing augmented reality tools to present concepts and make instant modifications based on client feedback.

Effective Communication Strategies

Establish clear channels of communication with clients. Use project management tools for transparency. Schedule regular check-ins throughout the project. Listen actively to client feedback and concerns. Clear communication prevents misunderstandings and ensures satisfaction.

Managing Client Expectations

Set realistic timelines and deliverables from the start. Explain the design and production process clearly. Provide detailed quotes and stick to them. Be honest about potential challenges or limitations. Managing expectations leads to smoother projects.

read This Blog: Chongqing 520m Building: A New Icon of Urban Innovation and Design

The Future of One Person Metal Mold Design Business

One-person metal mold design businesses are embracing digital technologies and cloud-based collaboration tools. This shift allows solo designers to compete with larger firms, offering specialized services and rapid prototyping capabilities.

Embracing New Technologies

Stay informed about emerging technologies like 3D printing. Consider incorporating augmented reality for design previews. Explore machine learning for optimizing designs. Adapt to new materials and manufacturing techniques. Embracing innovation keeps your business relevant.

Expanding Your Services

Consider offering design consultation services. Explore opportunities in rapid prototyping. Look into providing mold maintenance and repair services. Stay open to collaborations with larger firms. Diversifying services can create new revenue streams.

Frequently Asked Questions

How much capital do I need to start a metal mold design business?

Initial investment varies but typically ranges from $50,000 to $100,000, covering essential equipment, software, and workspace setup.

What qualifications do I need for this business?

A degree in engineering or design is beneficial. Experience in CAD and CNC machining is crucial. Certifications in specific software or techniques can be advantageous.

How do I price my services competitively?

Research market rates, calculate your costs, and consider your unique value proposition. Start with competitive pricing and adjust as you establish your reputation.

What are the biggest challenges in this industry?

Keeping up with technological advancements, managing client expectations, and dealing with competition are common challenges. Continuous learning and adaptability are key.

How can I protect my designs from being copied?

Use non-disclosure agreements with clients. Consider patenting unique designs. Maintain digital security to protect your files. Build strong relationships based on trust and quality.

Conclusion

Starting a one-person metal mold design business in 판금 requires dedication, skill, and business acumen. By focusing on quality, efficiency, and customer satisfaction, you can carve out a successful niche in this competitive industry. Stay adaptable, continue learning, and always strive for excellence in your designs.

Amelia is a skilled SEO expert with a strong focus on content writing, keyword research, and web development. With a dedication to delivering results, she helps businesses optimize their online presence and drive organic growth.

Her expertise ensures that clients stay ahead in the ever-evolving digital landscape